Moly - D

Moly - D two-shank heating element

The U shaped elements are most frequently used suspended with the bottom of the "U" down. The element consists of two cold ends (Lu) and a U-shaped hot section (Le). The cold ends are twice the diameter of the hot section and are attached by a weld. The extremities of the cold ends are metallized with aluminum to provide a low-resistance contact surface to which the electrical connections are made with flat braided aluminum straps.

The two-shank element is available in the following hot zone/cold end diameters: 3/6, 4/9, 6/12, 9/18 and 12/24.

These elements are available in two grades: MD-31 for element temperatures up to 1700°C (3100°F) and MD-33 for element temperatures up to 1800°C (3272°F).

Moly - D bent heating elements

The molybdenum disilicide material becomes soft and ductile about 1200°C. Suspending the elements from the cold ends and allowing the hot zone to hang vertically down is the most frequent method of use.

The Moly-D elements can be provided with bends in the cold end (Lu) of 30°, 45°, 90° or with bends in the hot zone (Le) of 90°. The hot zone (Le) is suspended vertically with the bottom of the "U" down. The bent element is available in the following hot zone/cold end diameters: 3/6, 4/9, 6/12, 9/18 and 12/24.

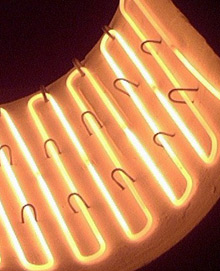

Moly - D multi-shank heating elements

For applications where the furnace roof is particularly low, the use of horizontally mounted elements can be used. In such cases, four-shank or multi-shank elements might be used where the surface temperature of the element will not exceed 1600°C. Available in Grade MD-31 in 3/6, 4/9, 6/12, 9/18 and 12/24 sizes. The multi-shank elements have advantages over two-shank elements in that the hot zones are longer, therefore fewer elements can be used and the cold end losses are reduced.

Moly - D heating element accessories

Moly-D aluminum straps, held in place by nuts and bolts, are available in two primary styles:

- Single Loop Straps for connecting binding post to element.

- Double loop for connecting element to element.

Moly-D holders are available in three styles:

- Ceramic type holders are available for the 6/12, 9/18 and 12/24 diameter elements. These holders offer higher temperature capabilities for use with elevated termination temperatures.

- Plate type holders are available for the 3/6, 4/9, and 6/12 diameter elements. These holders are used when a single hole is cut into the furnace wall for each element. A high-temperature fiber insulating board is installed to prevent heat from escaping.

- Metallic holders are available for the 3/6, 4/9, 6/12, 9/18 and 12/24 diameter elements. They work well in applications where spacing is restricted.

For more information please visit the I Squared R website by clicking here

Ways to order Moly - D

Call us now on 0044 1782 333377 and one of our heating element specialists will help you make your order as well as discuss any other heating element requirements you may have.

Email us now on sales@midlandelements.co.uk with your specific heating element requirements and we will call you back to discuss the details of your order and answer any questions you may have about your heating element requirements, or the services we can provide to help you and your business.

Why choose us for your Moly - D elements:

- Great reputation & customer service.

- Leading worldwide suppliers

- Parts for every type of furnace

- Fast replacement parts

- Competitively priced